October 2016 — News

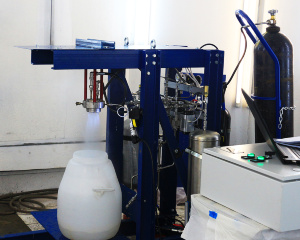

Flow tests of engine test stand

On Sunday, October 2 we conducted the final assembly and setup of the test stand for static firing. To receive and process sensor readings a monitoring & control board was conected and checked, strain gauges were adjusted and calibrated.

Besides, threaded joints were sealed, pipe joints were crimped and pressurization gas pipeline was upgraded for connecting larger volume cylinders.

First it was necessary to make waterflow tests to determine flow rates, perform leak checks and, of course, gain experience of work with feed system.

Read more...Test series with RD1-300M completed

We have completed series of flight tests for the control system onboard subsonic flying testbed with RD1-300M motors burning rocket candy. Four such engines having impulse of 300 N·s each were installed on the testbed, and were ignited in pairs during ascent.

The twelfth flight of the flying testbed was unsuccessful - motor burnthrough occurred after the launch, and battery thermal cutoff was triggered, causing control system shutdown. The flight became uncontrolled, and the parachute wasn't deployed, so the rocket landed hard.

Read more...Second launch of the supersonic flying testbed

On Saturday, September 3 in Kirov Oblast the second test launch of the supersonic flying testbed was made without installing the onboard flight control system.

The supersonic flying testbed is a two-stage rocket with total mass of 15 kg, most of which is solid fuel. It consists of ammonium perchlorate, aluminium, catalyst and polyester resin.

Shape of the axial channel of the first-stage engine - cylindrical, of second-stage engine - conical.

Video of the launch:

Read more...Assembly of the engine test stand continues

In late August we received all the components to complete the assembly of the engine test stand for testing bipropellant liquid rocket engines with thrust of up to 150 kgf. Shipping the necessary parts was delayed due to summer vacations of the suppliers staff.

Sadly, we were not able to test our engine at the test stand of Department 202 of MAI - for technical (the stand needs repair) and political (their management prefers not to take risks) reasons. Companies of the industry dealing with hydrogen peroxide were willing to help us, but the price for the test in the "industrial companies" is about four times the cost of creating our own test stand.

Thus, we decided to assemble the engine test stand on our own.

Read more...Successful test of a rocket with control system

On Saturday, August 20 our subsonic flying testbed performed another flight to verify one of the control system versions - based on Arduino.

The rocket design remained the same, and key modifications were introduced to the control system algorithms - number of calculations was reduced, accuracy of positioning of the servos was improved, and coefficients in the control law were adjusted..

Read more...Control system was tested in flight

In June-July our flying testbeds (test rockets, designed for testing the control system (CS) in real flight) flew twice.

Earlier we described the design of CS and flying testbed. Like in April flights, we launched two versions of the CS - one developed using

Read more...Catalyst tests for the liquid-propellant rocket engine

To ensure self-ignition of propellants of our liquid-propellant rocket engine, we have developed a special catalyst technology. Note that RDL-100S Atar rocket engine burns high-test peroxide (85-90%) and kerosene (TS-1).

The catalyst is located in a special chamber of the engine, into which the peroxide is fed as a liquid. The peroxide gets decomposed and enters the combustion chamber of the engine as heated steam and gas.

Read more...